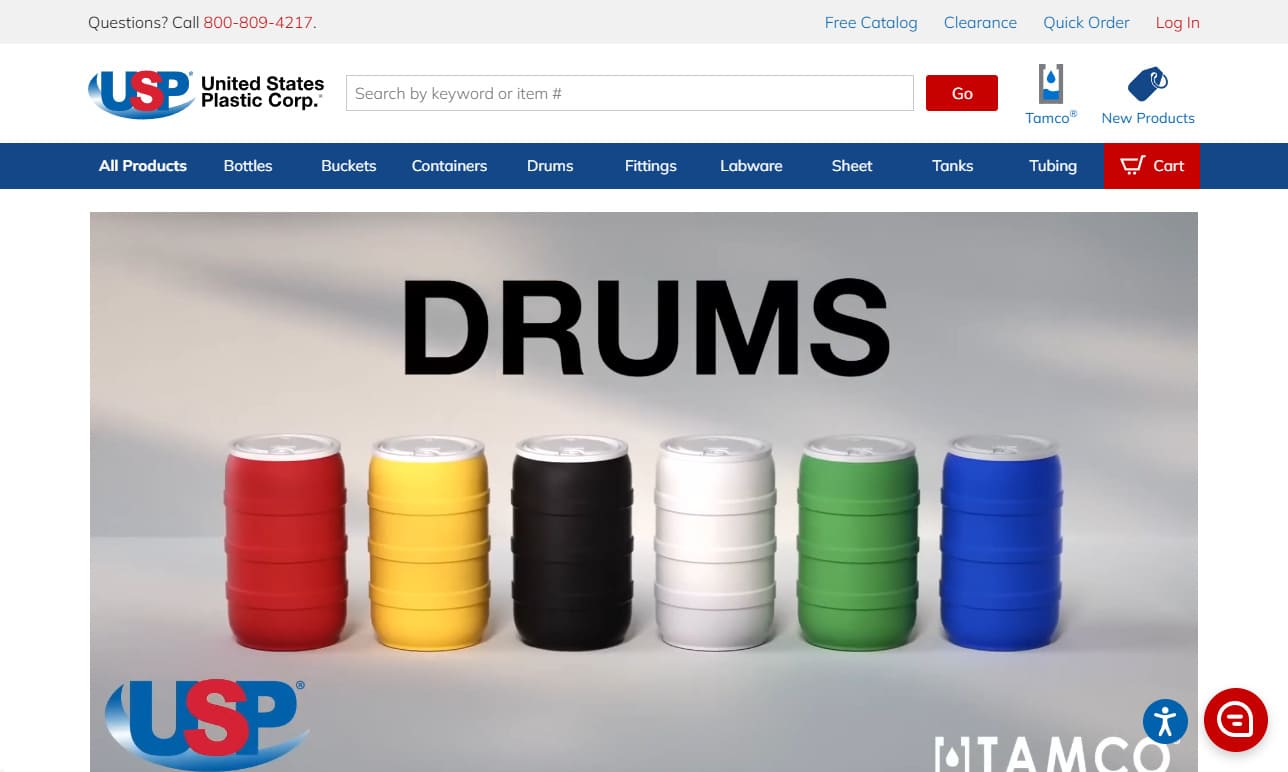

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

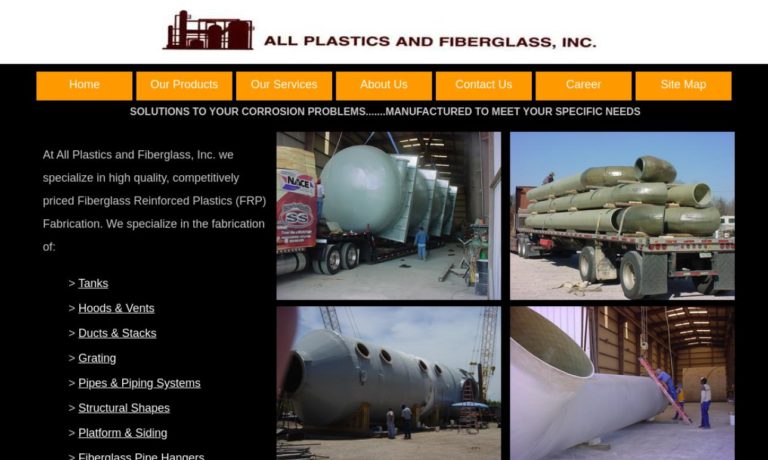

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

We are Boedeker Plastics, a leading supplier of high-performance plastics and composite materials. Our mission is to provide innovative solutions to our customers' most challenging material needs. With a focus on quality and customer satisfaction, we offer a comprehensive range of products and services to help our customers achieve their goals.

At ENSINGER Inc., we are dedicated to advancing the field of high-performance plastics by delivering materials that solve complex engineering challenges. We specialize in the development, production, and processing of thermoplastic materials that are engineered to perform in demanding applications across industries such as aerospace, automotive, medical, food processing, and industrial equipment.

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

More PVC Manufacturers

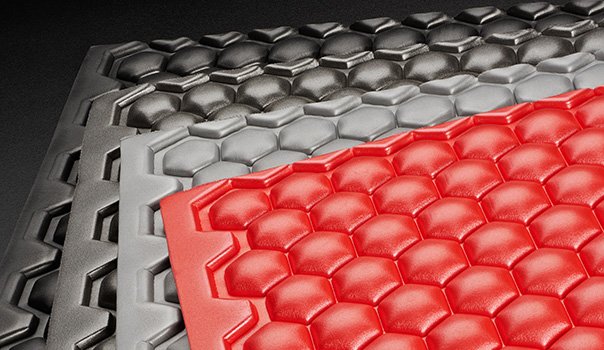

Industrial manufacturers in automotive, medical, plumbing and virtually every other industry use polyvinyl chloride for its versatility and durability as well as its price. Production of this thermoplastic requires much less petroleum than its polymer counterparts such as polystyrene, polyethylene and polycarbonate, allowing for significant savings.

Despite the wide use, there is growing concern for the impact polyvinyl chloride has on the environment and human health as it contains highly toxic elements that may leech into the ground or atmosphere. Although it is not typically recycled, thermal depolymerization and PVC recovery techniques are being developed to diminish the harmful effects of PVC refuse.

Still, alternatives such as wood, paper, copper, steel clay and chlorine free plastics are sought out until a more environmentally friendly solution to the PVC problem is developed.

While the chlorine present in PVC is essentially the reason for safety concerns regarding the material, it is also responsible for many of the benefits. PVC manufacturers create this plastic material through the polymerization of vinyl chloride monomeres (VCM). 57% of the mass of each polymer is chlorine.

Although mass, emulsion/dispersion and solution methods may all be utilized to produce this material, suspension polymerization is preferred. VCM and water are introduced into a reactor containing an initiator. If needed, additives such as heat stabilizers, lubricants, fillers and plasticizers are introduced at this time. These determine the properties of the particular type of PVC being produced. The reaction vessel continually mixes the solution keeping all particles suspended.

This ensures that the resulting PVC resin has a uniform particle size. After this processing is complete, the resin is dried and sieved. PVC manufacturers offer this material in several forms, typically in granulated powders, pellets, or pre-forms. As with most other plastics; extrusion, injection molding, stamping and casting are used to create stock shapes which may later be reworked into a final product or be used as such.

These include rods, billets, sheets and films. It is important to consider the dimensions, quantity and physical properties of PVC stock form or product to ensure compatibility with the intended use.

Die Cutting

Die Cutting Foam Fabricating

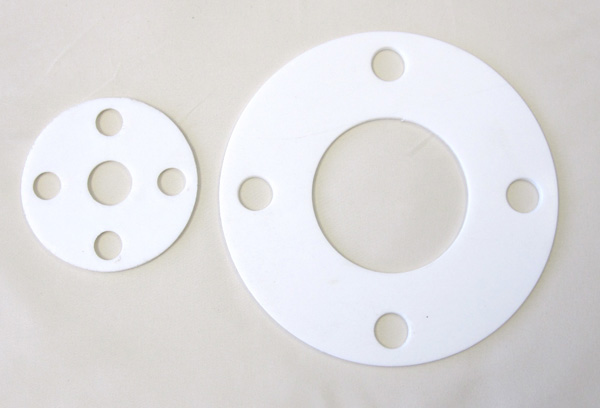

Foam Fabricating Gaskets

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

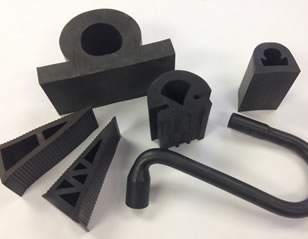

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services