United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

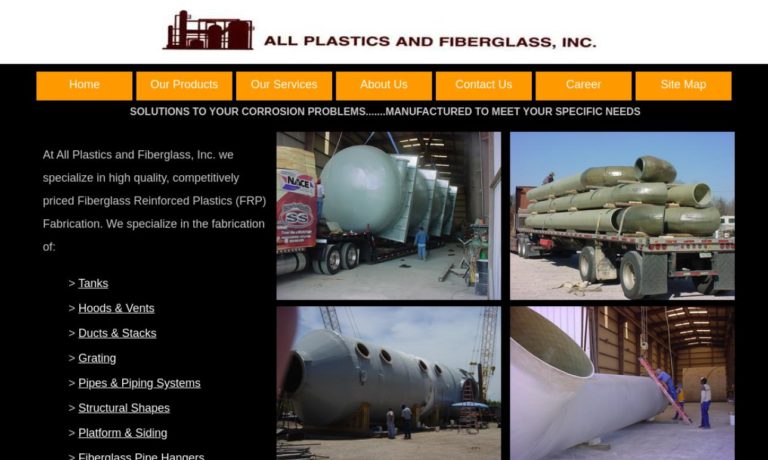

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

We are Boedeker Plastics, a leading supplier of high-performance plastics and composite materials. Our mission is to provide innovative solutions to our customers' most challenging material needs. With a focus on quality and customer satisfaction, we offer a comprehensive range of products and services to help our customers achieve their goals.

At ENSINGER Inc., we are dedicated to advancing the field of high-performance plastics by delivering materials that solve complex engineering challenges. We specialize in the development, production, and processing of thermoplastic materials that are engineered to perform in demanding applications across industries such as aerospace, automotive, medical, food processing, and industrial equipment.

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

More Polypropylene Manufacturers

Polypropylene (PP) is less dense than water and has a melting point of 320°F.

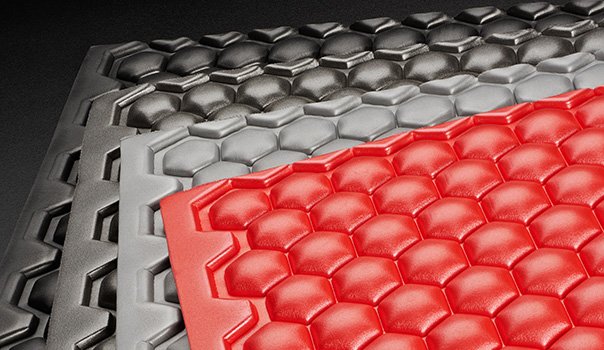

Polypropylene is often used to manufacture tools that need to be regularly sterilized. Polypropylene, which is commonly known as PP, is similar to polyethylene in that it is very affordable financially, but polypropylene is much stronger. Polypropylene has been available in sheet form since the 1960s. It is available in an assortment of thicknesses and can be manufactured to meet the needs of a variety of industries.

Like PVC, which is also known as polyvinyl chloride, it is also able to retain color, and is therefore available in a variety of hues as well. Polypropylene manufacturers can form this plastic material into a variety of shapes, including rods, pipes, tubes, film and many more. It can also be utilized as a fiber as well as a structural plastic.

Polypropylene may be shaped for further manufacturing through two major processes; extrusion and molding. The extrusion of PP involves melt blown and spun-bond fibers of polypropylene that are stretched and rolled up and shipped to manufacturers. The molding of PP involves heating, mixing and forcing the substance into a die cast mold, where it then hardens in that shape. Molds are made from sturdy metals or plastics that will not be affected nor will taint the melted plastic inside them.

Due to its many favorable attributes and low cost, polypropylene serves many purposes. Polypropylene is used to make various textiles, carpets, plastic furniture, food packaging, reusable containers, bottles, floating ropes, automotive components, military thermal clothing, and luggage. Because PP is dishwasher safe, it is also popular for manufacturing food storage containers.

For recycling purposes, the Society of Plastics Industry has given specific resin identification codes to plastics, according to their polymer structure. These numbers are specified on the bottom of recyclable objects; they are enclosed in a rounded triangle outlined in clockwise arrows. Polypropylene is recyclable and carries the number five under its PP symbol.

Research continues with polypropylene, as it does with many plastic substances. Scientists are experimenting with different synthesizing methods that change the chemical body of the plastic, resulting in physical variances. Some of these experiments are yielding new types of polypropylene that are very exciting, particularly those that have a softer feel then the rigidness of the current polypropylene substances.

Because these newer versions of polypropylene have more elasticity, they are that much more shatter resistant and therefore open up new options for industries already utilizing it.

Die Cutting

Die Cutting Foam Fabricating

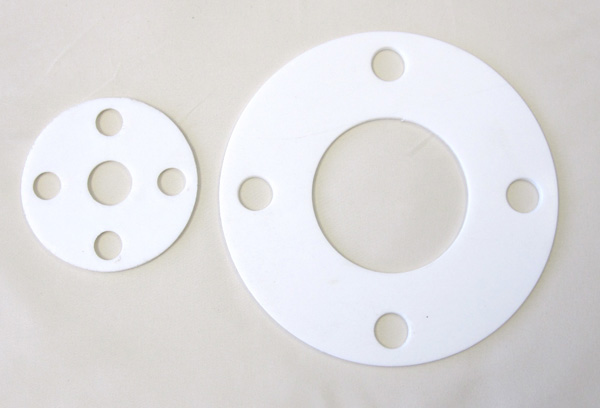

Foam Fabricating Gaskets

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

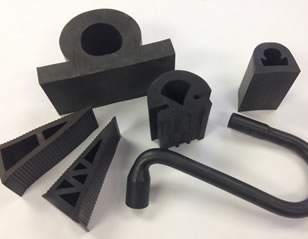

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services