United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

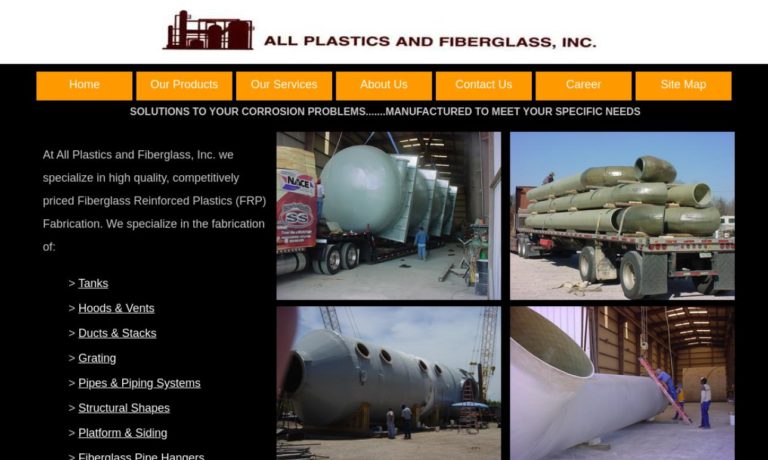

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

We are Boedeker Plastics, a leading supplier of high-performance plastics and composite materials. Our mission is to provide innovative solutions to our customers' most challenging material needs. With a focus on quality and customer satisfaction, we offer a comprehensive range of products and services to help our customers achieve their goals.

At ENSINGER Inc., we are dedicated to advancing the field of high-performance plastics by delivering materials that solve complex engineering challenges. We specialize in the development, production, and processing of thermoplastic materials that are engineered to perform in demanding applications across industries such as aerospace, automotive, medical, food processing, and industrial equipment.

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

More Polycarbonate Manufacturers

Polycarbonate: Properties, Applications, and Advantages

Polycarbonate is a high-performance thermoplastic polymer recognized for its outstanding light transmission, excellent impact resistance, and superior dimensional stability. This unique combination of characteristics makes polycarbonate a preferred choice in a wide variety of industries, from construction and automotive manufacturing to electronics and medical devices. If you are searching for a versatile plastic that combines strength, clarity, and adaptability, polycarbonate stands out as an ideal solution.

Key Characteristics of Polycarbonate

When comparing engineering plastics, polycarbonate is often highlighted due to its balanced properties:

- High light transmission: Allows up to 90% of visible light to pass through, making it an excellent alternative to glass in glazing and optical applications.

- Exceptional impact resistance: Virtually unbreakable, polycarbonate can withstand significant force and stress. It is approximately 250 times stronger than standard glass and far surpasses acrylic in durability.

- Machinability and thermoformability: Polycarbonate sheets and rods can be easily machined, cut, drilled, and thermoformed into custom shapes without losing integrity.

- Good dimensional stability: Maintains its shape and size even under varying temperature and humidity conditions.

- Lightweight: About half the weight of glass and even lighter than acrylic, making it ideal for weight-sensitive applications.

- FDA compliant: Certain grades of polycarbonate meet FDA requirements for food contact, making them suitable for food processing equipment and containers.

Polycarbonate vs. Acrylic: Which is Better?

Buyers often compare polycarbonate and acrylic when selecting transparent plastics for projects. While both are thermoplastic polymers that offer clarity and are easier to fabricate than traditional glass, there are substantial differences to consider:

- Strength: Polycarbonate is significantly tougher and more shatter-resistant than acrylic. Where acrylic offers 10-20 times the impact resistance of glass, polycarbonate is virtually unbreakable and even used in bullet-resistant applications.

- Weight: Polycarbonate is approximately one-third the weight of acrylic, making it ideal for portable or structural uses where reducing mass is essential.

- Thermoforming and fabrication: Both materials can be molded and reshaped with heat, but polycarbonate offers superior flexibility, allowing for more complex or curved designs.

- Cost considerations: While polycarbonate generally carries a higher price tag than acrylic or glass, its extended lifespan and fewer replacements often justify the initial investment.

- Environmental impact: As thermoplastics, both polycarbonate and acrylic can be recycled, reducing their environmental footprint compared to thermoset plastics that cannot be remelted or reformed.

Wondering which material is right for your application? Ask yourself:

- Do you need maximum impact resistance or is scratch resistance more important?

- Will your project benefit from lighter materials while maintaining clarity?

- Is cost or long-term durability your primary concern?

Thermoplastic Polymers: Polycarbonate and Beyond

Understanding the family of thermoplastic polymers helps in selecting the best material for your project. Polycarbonate and acrylic are both thermoplastics, meaning they can be repeatedly melted, reshaped, and recycled. This makes them more sustainable choices compared to thermoset plastics, which harden permanently after being set.

Other common thermoplastic materials include:

- Delrin® (Acetal Polyoxymethylene): Known for its durability, strength, and machinability, Delrin is widely used in precision parts like gears, bearings, and bushings.

- Polystyrene (PS): Available both as a rigid plastic and as foam (Styrofoam), polystyrene is commonly found in packaging, disposable cutlery, and insulation.

- PVC (Polyvinyl Chloride): Appreciated for its ability to hold vivid colors and its chemical resistance, PVC is frequently used for pipes, window frames, furniture, and decorative home products.

Where is Polycarbonate Used? Common Applications

Are you exploring polycarbonate applications for your business or personal project? Polycarbonate’s unique blend of properties enables its use in a broad spectrum of industries:

- Electronics and IT: Used for manufacturing CDs, DVDs, Blu-ray discs, smartphone cases, and electronic housings due to its excellent electrical insulation and durability.

- Construction and architecture: Clear and colored polycarbonate panels are popular in skylights, roofing, safety glazing, window replacements, and greenhouses thanks to high impact resistance and UV protection options.

- Automotive and transportation: Polycarbonate is used for headlamp lenses, instrument panels, sunroofs, and interior guards, leveraging its lightweight and shatterproof qualities to improve vehicle safety and fuel efficiency.

- Security and safety: Polycarbonate sheets are the material of choice for shatter-resistant display cases, security barriers, riot shields, face shields, machine guards, and burglar-resistant glazing due to their toughness and clarity.

- Medical and laboratory equipment: Sterilizable grades of polycarbonate are utilized in surgical instruments, incubators, oxygenators, and drug delivery systems, where strength, transparency, and biocompatibility matter.

- Vision care: The most popular material for corrective lenses, safety glasses, and sunglasses thanks to high refractive index, lightweight, and the ability to block harmful UV rays.

- Consumer products: Sports equipment, reusable water bottles, baby bottles (BPA-free grades), and household gadgets often feature polycarbonate for its resilience and clarity.

Looking for more detailed information? Consider these questions:

- What are the best polycarbonate grades for outdoor applications?

- How does polycarbonate compare to glass in terms of thermal insulation?

- Is polycarbonate safe for food contact and medical applications?

Vision Care: Why Polycarbonate Lenses Lead the Market

Polycarbonate has revolutionized the eyewear industry.

- High refractive index: Polycarbonate lenses bend light more efficiently, allowing for thinner, lighter corrective lenses compared to traditional glass or plastic alternatives.

- Safety: Their shatterproof nature makes them ideal for children’s eyewear, sports goggles, and protective eyewear where accidental impacts are a concern.

- UV protection: Polycarbonate naturally blocks nearly 100% of harmful UV rays, reducing the risk of eye diseases linked to sun exposure.

- Customization: Available in scratch-resistant, anti-reflective, and photochromic (light-responsive) coatings, making them suitable for sunglasses and fashion eyewear.

Searching for prescription lenses? Compare polycarbonate to high-index plastic and Trivex lenses for optimal comfort, performance, and cost.

Polycarbonate Product Forms and Customization

Polycarbonate is available in a range of forms to suit every fabrication and design need:

- Polycarbonate sheets: Offered in clear, tinted, and multiwall varieties for glazing, roofing, and machine guarding applications.

- Polycarbonate rods and tubes: Used in industrial, chemical, and laboratory settings for their strength and machinability.

- Polycarbonate films: Ideal for optical displays, touch screens, graphic overlays, and membrane switches due to high optical clarity and flexibility.

- Custom-molded polycarbonate: Injection molding enables mass production of intricate, high-precision parts for automotive, electronics, and consumer goods.

When specifying polycarbonate, consider factors such as UV resistance, flame retardancy, anti-static properties, and glass-filled grades for added strength and stiffness.

Benefits of Using Polycarbonate Plastics

Why do engineers, architects, and manufacturers increasingly choose polycarbonate over other plastics and glass?

- Unmatched durability: Withstands repeated impacts without cracking or shattering, extending the service life of products and structures.

- Design flexibility: Easy to cut, shape, form, and bond, supporting creative and complex designs in architectural and engineering projects.

- Thermal stability: Performs well over a wide temperature range, maintaining strength and clarity from -40°F to 280°F.

- Fire resistance: Self-extinguishing grades are available for use in environments requiring flame retardancy.

- Optical clarity: Maintains transparency over time, resisting yellowing and hazing even with outdoor exposure.

- Lightweight construction: Reduces transportation and installation costs, and enables innovative product designs.

- Recyclability: Supports circular economy initiatives by being fully recyclable, reducing landfill waste.

Polycarbonate vs. Glass: Performance, Cost, and Safety

If you are evaluating polycarbonate vs. glass for your next project, consider the following:

- Strength and safety: Polycarbonate is virtually unbreakable, making it ideal for applications where safety and security are critical, such as schools, hospitals, and public transportation.

- Weight: At less than half the weight of glass, polycarbonate reduces structural loads and simplifies handling and installation.

- Cost of ownership: While initial material costs may be higher, polycarbonate's durability and low maintenance requirements can lead to significant long-term savings.

- Thermal insulation: Multiwall polycarbonate sheets offer superior insulation compared to single-pane glass, improving energy efficiency for building envelopes.

Need help choosing between polycarbonate and glass? Contact our materials experts for detailed product comparisons and project-specific recommendations.

Frequently Asked Questions About Polycarbonate

- Is polycarbonate plastic safe? Yes, FDA-approved and BPA-free polycarbonate grades are available for food contact and medical use. Always verify compliance with regulatory standards for your specific application.

- How does polycarbonate handle UV exposure? UV-stabilized polycarbonate resists yellowing, cracking, and degradation, making it suitable for outdoor and greenhouse applications.

- Can polycarbonate be recycled? Polycarbonate is a recyclable plastic. Contact local recycling centers to confirm accepted plastics and recycling procedures in your area.

- What are the limitations of polycarbonate? While extremely tough, polycarbonate is softer than glass and can scratch more easily. Specialty coatings are available to improve scratch resistance.

- How is polycarbonate fabricated? Polycarbonate can be cut, drilled, routed, thermoformed, and bonded using standard plastic fabrication tools and adhesives.

How to Select the Right Polycarbonate for Your Project

Choosing the best polycarbonate material involves evaluating several key factors:

- Environmental conditions: Will the material be exposed to sunlight, chemicals, or extreme temperatures?

- Mechanical requirements: What level of impact, load, and wear must the product withstand?

- Optical needs: Is transparency or specific tinting required?

- Regulatory compliance: Does the application require FDA, UL, or other certifications?

- Budget: Consider both upfront costs and long-term savings from reduced maintenance and replacement.

Ready to take the next step? Request a sample or contact our sales team to discuss your polycarbonate requirements and receive expert guidance tailored to your industry and application.

Polycarbonate Suppliers and Manufacturers

Finding a reliable polycarbonate supplier is crucial for ensuring consistent quality and supply. Leading manufacturers offer a range of polycarbonate products, including sheets, rods, tubes, and custom-molded parts in various grades for industrial, commercial, and consumer use.

- Bulk polycarbonate orders: Many suppliers offer volume pricing and just-in-time delivery programs.

- Custom fabrication: CNC machining, laser cutting, and custom molding services are available for unique project needs.

- Technical support: Top suppliers provide engineering assistance, documentation, and compliance certifications.

For more information, explore our polycarbonate suppliers directory or contact us for personalized assistance.

Conclusion: Why Choose Polycarbonate?

Polycarbonate is a premier engineering plastic that delivers unbeatable strength, clarity, and versatility. Whether you need shatterproof glazing, durable machine guards, energy-efficient roofing, or advanced optical lenses, polycarbonate offers a reliable solution that outperforms glass and many other plastics. With its environmental benefits, wide range of applications, and customizable properties, polycarbonate is the go-to material for demanding projects across industries.

Ready to get started?Request a quote or speak with our polycarbonate experts today to find the perfect material for your needs.

Die Cutting

Die Cutting Foam Fabricating

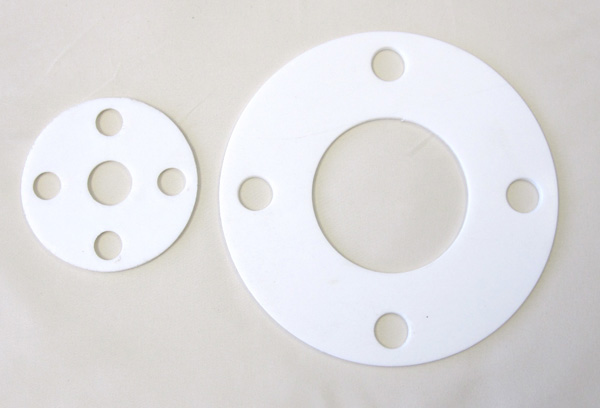

Foam Fabricating Gaskets

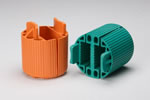

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

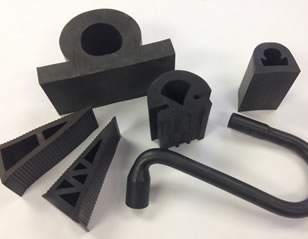

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services