United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

We are Boedeker Plastics, a leading supplier of high-performance plastics and composite materials. Our mission is to provide innovative solutions to our customers' most challenging material needs. With a focus on quality and customer satisfaction, we offer a comprehensive range of products and services to help our customers achieve their goals.

At ENSINGER Inc., we are dedicated to advancing the field of high-performance plastics by delivering materials that solve complex engineering challenges. We specialize in the development, production, and processing of thermoplastic materials that are engineered to perform in demanding applications across industries such as aerospace, automotive, medical, food processing, and industrial equipment.

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

More Plastic Film Manufacturers

Comprehensive Guide to Plastic Film: Types, Applications, and Manufacturing Processes

Plastic films are engineered materials composed of long-chain polymers, in which monomers form robust covalent bonds both among themselves and with other molecules. These films are a foundational material in modern industry, offering exceptional versatility, durability, and adaptability for a wide range of applications. Understanding the various types of plastic films, their properties, manufacturing processes, and end-use industries is essential for buyers, engineers, and decision-makers seeking high-performance film solutions.

Types of Plastic Films and Their Chemical Structures

The most prevalent chemical systems used in the production of plastic films include polyethylene (PE), polycarbonate (PC), polystyrene (PS), polyvinyl chloride (PVC), and polyoxymethylene (POM), among others. Each of these polymers has specific physical and chemical characteristics that make them suitable for particular applications:

- Polyethylene Film (PE Film): Highly flexible, chemically resistant, and available in several densities (LDPE, HDPE), making it ideal for packaging, liners, and agricultural film.

- Polycarbonate Film (PC Film): Known for its optical clarity, impact resistance, and heat stability—widely used in electronics, automotive, and security documents.

- Polystyrene Film (PS Film): Offers rigidity and transparency, commonly found in food packaging and laboratory applications.

- Polyvinyl Chloride Film (PVC Film): Provides excellent chemical resistance, flexibility, and flame retardancy—perfect for medical devices, signage, and building materials.

- Polyoxymethylene Film (POM Film): Features high mechanical strength and dimensional stability—frequently used for precision parts and electrical applications.

What Are the Most Common Plastic Film Materials?

If you are evaluating which plastic film material best fits your application, consider how properties such as clarity, strength, chemical resistance, and flexibility influence performance. For instance, LDPE film is prized for its low cost and flexibility, while HDPE film provides increased strength and puncture resistance. Polycarbonate film is selected for demanding environments requiring impact resistance and thermal stability.

Key Applications of Plastic Film Across Industries

While the ubiquity of plastics is apparent in everyday life, the critical roles played by plastic film in industry are often underappreciated. Plastic film serves as an essential solution in applications where lightweight, flexible, and protective materials are required. Here are some of the most prominent uses:

- Packaging Film: Used in the production of plastic bags, shrink wrap, stretch film, and vacuum pouches. Its barrier properties help preserve freshness, prevent contamination, and extend shelf life in food packaging.

- Protective Film: Shields surfaces during manufacturing, transportation, and installation. This includes protective films for electronics, automotive components, appliances, and glass.

- Construction Film: Plastic sheeting and vapor barriers are used for moisture control, insulation, and concrete curing blankets in building and civil engineering projects.

- Agricultural Film: Mulch films, greenhouse covers, and silage wraps enhance crop yields, regulate soil temperature, and provide weather protection.

- Medical and Healthcare Film: Films are used in sterile packaging, surgical drapes, IV bags, and diagnostic device components due to their biocompatibility and barrier properties.

- Industrial and Technical Films: Anti-static films, flame-retardant films, and EMI shielding films protect sensitive electronics, semiconductors, and aerospace equipment.

- Other Applications: Wood coating, crop and seed protection, drywall coating, and marine protective films.

Where Is Plastic Film Most Commonly Used?

Industries such as building and construction, packaging, agriculture, aerospace, automotive, electronics, food processing, semiconductor, marine, medical, and military rely on plastic film for its tailored performance characteristics. Whether you need moisture barriers, UV protection, electrical insulation, or chemical resistance, there is a specialized plastic film solution for your requirements.

Enhancing Performance: Treatments and Additives in Plastic Film

Plastic films are often engineered with specialized treatments and additives to deliver enhanced performance for specific environments and applications. Key enhancements include:

- Moisture Resistance: Prevents water vapor transmission, critical for packaging, construction, and agricultural films.

- Anti-Static Control: Reduces static build-up, protecting sensitive electronics and cleanroom environments.

- Electrostatic Discharge (ESD) Protection: Shields components from damaging static electricity, essential for semiconductor and electronics packaging.

- Electromagnetic Interference (EMI) Shielding: Prevents interference in high-frequency electronic devices.

- Flame Retardancy: Meets safety standards in building, transportation, and electronics sectors.

- UV Stabilization: Prolongs outdoor film life by preventing degradation from sunlight exposure.

- Optical Clarity: Achieved via additives and processing to meet stringent requirements for display films and optical applications.

- Mechanical Reinforcement: Incorporates fillers and plasticizers to enhance toughness, flexibility, and impact resistance.

What Are the Benefits of Treated Plastic Films?

By selecting the appropriate combination of base resin, additives, and surface treatments, plastic film manufacturers can optimize films for specific use cases. Enhanced films offer improved durability, cost efficiency, and safety—factors that are crucial for industries where product integrity is paramount.

Manufacturing Methods for Plastic Film: From Raw Material to Finished Product

The manufacturing processes used to produce plastic film are engineered for efficiency, scalability, and precision. Key fabrication techniques include:

- Extrusion: The most common method, where plastic pellets are melted and forced through a die to create a continuous film. Variants include sheet extrusion and blown film extrusion.

- Blown Film Extrusion: A specialized process in which molten polymer is extruded through a circular die to form a tube. Air is introduced to inflate the tube, forming a thin, uniform bubble. The film is then cooled, flattened, and wound into rolls.

- Casting: Molten polymer is poured onto a cooled surface and spread to the desired thickness. This method produces films with excellent optical clarity and dimensional stability.

- Calendering: Polymer is pressed through heated rollers to achieve precise thickness and surface finish—commonly used for PVC films.

- Coating and Laminating: Additional layers or coatings may be applied to the base film to create composite materials with tailored properties.

How Is Plastic Film Manufactured?

If you are researching how plastic film is made, consider the importance of process selection. For example, blown film extrusion is preferred for high-volume packaging films, while casting is chosen for demanding optical applications. Consult with experienced plastic film suppliers to determine the optimal process for your requirements.

Customization: Tailoring Plastic Film for Specialized Applications

Modern plastic film manufacturing is highly customizable. Through the use of advanced additives, colorants, and co-extrusion technology, films can be produced to meet precise specifications for thickness, width, mechanical strength, barrier properties, and surface finish.

- Multi-Layer Films: Co-extrusion enables the creation of films with several functional layers, combining properties such as moisture resistance, oxygen barrier, and printability.

- Surface Treatments: Corona treatment, flame treatment, or chemical priming improve ink adhesion and print quality for flexible packaging and labeling.

- Functional Additives: Heat stabilizers, UV absorbers, slip agents, anti-blocking agents, and antimicrobial additives address specific performance requirements.

Can Plastic Film Be Customized for My Industry?

Whether you require high-barrier packaging film, anti-fog agricultural film, or electrically conductive film for electronics, leading plastic film manufacturers can deliver a solution tailored to your exact needs. Work with your supplier to define performance criteria, regulatory compliance, and end-use conditions.

Evaluating Plastic Film: Key Decision Factors for Buyers

When selecting a plastic film supplier or specifying a film for your project, consider the following decision factors to ensure optimal performance and value:

- Material Selection: Does the polymer type align with chemical, thermal, and mechanical requirements?

- Barrier Properties: What level of moisture, gas, or aroma barrier is required for your application?

- Thickness and Gauge: How does film thickness impact strength, flexibility, and cost?

- Surface Characteristics: Is clarity, texture, or printability important for your product?

- Regulatory Compliance: Does the film meet industry standards such as FDA, RoHS, or REACH?

- Environmental Impact: What are the options for recycling or using biodegradable films?

- Supply Chain and Lead Time: Can the supplier deliver consistent quality within your project timeline?

How Do I Choose the Right Plastic Film for My Application?

To select the best plastic film for your project, begin with a detailed analysis of your performance needs, regulatory constraints, and budget. Request samples and technical data sheets from multiple plastic film manufacturers, and consider conducting in-house or third-party testing before full-scale adoption.

Emerging Trends and Innovations in Plastic Film Technology

The plastic film industry is continually evolving to meet the demands of sustainability, performance, and regulatory compliance. Key trends include:

- Biodegradable and Compostable Films: Made from renewable resources such as PLA, PHA, and starch blends, these films reduce environmental impact and support circular economy initiatives.

- Recyclable Mono-Material Films: Designed to improve recycling rates by simplifying material streams.

- Smart Films: Incorporating sensors, RFID, or antimicrobial agents for intelligent packaging and medical applications.

- High-Barrier Films: Advanced multilayer constructions for extended shelf life and product protection.

- Lightweighting: Reducing film thickness without sacrificing performance to lower material costs and carbon footprint.

What Are the Latest Innovations in Plastic Film?

Buyers and product developers increasingly seek sustainable plastic film solutions that meet environmental goals without compromising performance. Ask your supplier about options for compostable, recyclable, or bio-based films, as well as the latest advancements in functional coatings and smart packaging technology.

Frequently Asked Questions About Plastic Film

- What is the difference between cast and blown film? Cast film offers superior clarity and uniform thickness, while blown film provides balanced mechanical properties and cost-efficient high-volume production.

- Can plastic film be printed or laminated? Yes, films can be printed using flexographic, gravure, or digital printing, and can be laminated with other materials for enhanced performance.

- Are there environmentally friendly plastic film options? Yes, options include compostable, biodegradable, and recyclable films. Many manufacturers now offer eco-friendly alternatives for packaging and industrial use.

- How do I determine the right thickness for my film application? Thickness selection depends on the required strength, barrier properties, and cost considerations. Consult with your supplier for recommendations based on your specific use case.

- Who are leading plastic film manufacturers? Browse trusted suppliers and industry directories to find qualified manufacturers with expertise in your desired material and application area.

Start Your Plastic Film Project: Next Steps

Ready to specify or purchase plastic film for your next project? Consider the following action steps to ensure a successful outcome:

- Define your performance requirements and preferred polymer type.

- Request technical data sheets and regulatory certifications from potential suppliers.

- Ask about available customization options, including additives, surface treatments, and multi-layer constructions.

- Evaluate sample films under real-world conditions before committing to large-volume orders.

- Stay informed about industry trends—explore sustainable and smart film solutions.

Need Help Selecting the Right Plastic Film?

Contact an experienced plastic film supplier or manufacturer for expert guidance on material selection, custom fabrication, and technical support. Use our directory of polycarbonate and specialty film manufacturers to start your search and connect with industry leaders.

Conclusion

Plastic films are indispensable materials in today's global economy, serving as critical components across packaging, construction, agriculture, healthcare, and technology markets. By understanding the properties, manufacturing processes, applications, and emerging innovations in plastic film technology, buyers and engineers can make informed decisions that maximize product value, sustainability, and performance. For best results, partner with a reputable plastic film manufacturer who can deliver tailored solutions to meet your unique needs.

For additional information, technical resources, or to request a quote, explore our complete plastic film manufacturer directory or contact us for personalized assistance.

Die Cutting

Die Cutting Foam Fabricating

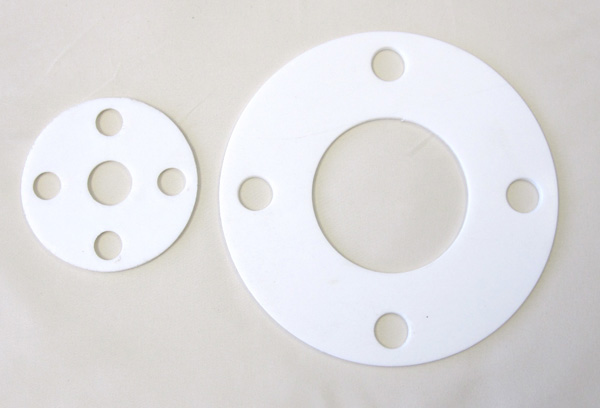

Foam Fabricating Gaskets

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

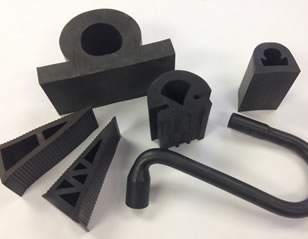

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services