United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

We are Boedeker Plastics, a leading supplier of high-performance plastics and composite materials. Our mission is to provide innovative solutions to our customers' most challenging material needs. With a focus on quality and customer satisfaction, we offer a comprehensive range of products and services to help our customers achieve their goals.

At ENSINGER Inc., we are dedicated to advancing the field of high-performance plastics by delivering materials that solve complex engineering challenges. We specialize in the development, production, and processing of thermoplastic materials that are engineered to perform in demanding applications across industries such as aerospace, automotive, medical, food processing, and industrial equipment.

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

More Delrin Manufacturers

Delrin is the well-known trademark for a specific grade of acetal polyoxymethylene (POM), a high-performance engineering thermoplastic that is frequently used as a lightweight, durable alternative to metal components in a wide range of commercial, industrial, and residential applications. POM, which includes both homopolymer and copolymer variations, is valued for its high mechanical strength, low friction, and exceptional dimensional stability. These properties make Delrin a preferred material for precision parts that require consistent performance in demanding environments. If you’re researching “What is Delrin used for?” or “Where to buy Delrin plastic?”, you’re in the right place to learn about its manufacturing, applications, benefits, and how to select the right Delrin supplier for your needs.

What Is Delrin? Understanding the Material and Its Advantages

Delrin, a brand name for polyoxymethylene (POM), is a type of acetal resin renowned for its outstanding combination of stiffness, toughness, and low friction. It is often compared with other engineering plastics like nylon, PTFE (Teflon), and UHMW, but Delrin is especially sought after when users require high mechanical strength, fatigue resistance, and excellent machinability. If you are searching for “Delrin vs nylon” or “acetal vs Delrin,” note that Delrin is actually a homopolymer acetal, while other acetals may be copolymers, each with unique performance characteristics.

Delrin is widely recognized for its:

- High tensile and impact strength

- Excellent dimensional stability across broad temperature ranges

- Low coefficient of friction for smooth sliding and motion applications

- Superior resistance to moisture, solvents, fuels, and a variety of chemicals

- Ease of machining, milling, turning, and fabrication

- Fatigue endurance and resistance to creep under load

- Electrical insulating properties, making it suitable for electrical and electronic components

Delrin Manufacturing Process: How Is Delrin Made?

The manufacturing of Delrin begins with the polymerization of formaldehyde. The process differs for homopolymer and copolymer grades, but both methods yield robust thermoplastic resins suitable for demanding engineering applications.

For Delrin homopolymer, anhydrous formaldehyde reacts with alcohol to create semiformal, which serves as the precursor. This semiformal is then dehydrated and polymerized through ionic catalysis, forming polyoxymethylene. The resulting polymer is stabilized with acetic anhydride, ensuring long-term durability and performance.

In the case of Delrin copolymers, formaldehyde is converted to trioxane via acid catalysis, then purified and subsequently polymerized to form the copolymer resin. Both types are typically supplied as hot, granular pellets that can be processed using standard plastic fabrication techniques.

Key Delrin manufacturing methods include:

- Injection molding: For producing complex, high-precision parts in high volumes.

- Extrusion: Used to make rods, sheets, tubes, and other stock shapes for machining.

- Rotational and blow molding: Ideal for creating hollow or large stock shapes.

- Precision machining (turning, milling, drilling): For custom or low-volume part production where tight tolerances are critical.

Because Delrin is a thermoplastic, it can be reheated, remolded, or re-extruded as required, making it a highly versatile material for plastic fabrication and prototyping. When selecting a mold, keep in mind that POM exhibits a shrinkage rate of up to 2%, which should be accounted for during design and fabrication to ensure dimensional accuracy.

Delrin Grades and Modifications

Delrin is available in a variety of grades, each tailored for specific performance requirements:

- Standard Delrin (Delrin 150, Delrin 500): General-purpose engineering plastic for machining and molding.

- Delrin AF: Filled with PTFE for enhanced wear properties and lower friction.

- Glass-filled Delrin: Improved stiffness and strength for structural applications.

- UV-stabilized and flame-retardant Delrin: For outdoor or electrical use.

- FDA-compliant Delrin: Suitable for food processing and medical device applications.

Common modifications include thermal and oxidative stabilizers, lubricants, and fillers to improve Delrin’s thermal, chemical, and wear properties. These enhancements make Delrin an ideal solution for highly specialized environments, such as the automotive, aerospace, and medical industries.

Delrin Component Assembly: Methods and Best Practices

When designing or specifying Delrin parts, consider the available assembly methods, as the material’s unique properties enable both flexible and robust joining options. Some popular assembly techniques for Delrin components include:

- Mechanical Fastening: Self-tapping screws, snap-fits, and press-fits allow for easy assembly and disassembly, making Delrin ideal for modular or serviceable products.

- Permanently Joined Assemblies: Welding, adhesives, and riveting are used for durable, high-strength joints in production environments.

- Prototyping & Low-Volume Production: Adhesives may be sufficient for prototypes or small runs, but may not offer the mechanical strength required for final products. For maximum strength and longevity, mechanical fasteners or welded joints are preferred.

Prior to assembly, ensure surfaces are clean and degreased using sandpaper or appropriate chemical cleaners. This step is essential for optimal adhesion and joint integrity, especially when using adhesives or welding techniques. If you’re wondering, “Can Delrin be glued?” or “How to bond Delrin to metal?”, manufacturers often recommend specialized adhesives or surface treatments to enhance bond strength.

Benefits of Using Delrin: Why Choose Delrin Over Metal or Other Plastics?

- Metal Replacement: Delrin offers an ideal balance between the desirable properties of metal and polymer materials. With its high impact strength and load-bearing capabilities, Delrin often replaces metals in gears, bushings, and mechanical components, reducing overall weight and cost.

- Superior Dimensional Stability: Delrin maintains its precise shape and size even when exposed to fluctuating temperatures and humidity, ensuring reliability in precision applications such as bearings, gears, and measuring instruments.

- Moisture and Chemical Resistance: Unlike many conventional plastics, Delrin resists water absorption and maintains its mechanical properties in humid or chemically aggressive environments. It is ideal for use in pumps, valves, plumbing fixtures, and components exposed to fuels and solvents.

- High Strength and Toughness: Delrin’s combination of toughness, impact resistance, and fatigue endurance make it suitable for parts subjected to repetitive stress or high loads, such as automotive and industrial machinery components.

- Machinability and Fabrication Flexibility: Delrin is easy to machine and fabricate using standard metalworking and plastic fabrication tools, allowing for precise customization, prototyping, and low- to high-volume manufacturing.

- Excellent Wear and Abrasion Resistance: Delrin’s low friction and high wear resistance make it a preferred choice for sliding parts, gears, bearings, bushings, and conveyor components exposed to regular contact and movement.

- Electrical Insulation: Delrin’s non-conductive properties make it an excellent choice for electrical housings, connectors, and insulators in consumer electronics and industrial automation.

Looking for a material that balances cost, performance, and manufacturability? Delrin’s unique set of properties makes it a top choice for engineers and procurement teams seeking reliable, long-lasting solutions in demanding environments.

Delrin Applications: Where Is Delrin Used?

Delrin is one of the most versatile engineering plastics, with applications spanning nearly every major industry. If you need to know “What is Delrin used for?” or “Can Delrin replace metal in my application?”, consider these common use cases:

- Automotive: Gears, bushings, throttle bodies, fuel system components, door lock assemblies, seat belt mechanisms, and window guides.

- Industrial Machinery: Bearings, gears, conveyor rollers, pump housings, valve parts, and wear guides for equipment requiring high strength and low friction.

- Consumer Electronics: Connectors, switches, housings, covers, and insulation components.

- Medical Devices: Insulin pens, inhalers, surgical tools, dental instruments, and diagnostic equipment.

- Plumbing and Fluid Handling: Valve bodies, pump impellers, water meter components, and plumbing fittings.

- Food Processing: FDA-compliant Delrin grades are used in conveyor chains, food contact parts, and bottling equipment.

- Textile and Packaging Equipment: Gears, cams, and rollers that benefit from Delrin’s wear resistance and low friction.

- 3D Printing and Prototyping: Delrin’s machinability and dimensional stability make it popular for rapid prototyping and functional testing.

Delrin is often the material of choice when replacing metal parts to reduce weight, improve corrosion resistance, and lower production costs. Manufacturers offer various special grades to meet specific customer requirements, including enhanced lubrication, improved UV stability, or compliance with regulatory standards.

Delrin for Custom Machined Parts

Machinists and engineers regularly choose Delrin for custom CNC machining, as it can be easily milled, turned, or drilled into precise shapes. Delrin’s low internal stresses and consistent material properties result in tight tolerances and high-quality surface finishes, making it ideal for functional prototypes, jigs, and fixtures.

Delrin in High-Performance Environments

Thanks to its chemical resistance and durability, Delrin is widely used in harsh environments such as the petrochemical, oil and gas, and marine industries. Delrin fittings and components are ideal for systems transporting fuels, solvents, and corrosive fluids, providing long service life and minimal maintenance requirements.

How to Select the Right Delrin Manufacturer or Supplier

Choosing a reliable Delrin manufacturer or plastic machining partner is critical to ensuring product quality, material traceability, and cost-effectiveness. When you’re ready to purchase Delrin stock shapes, machined parts, or custom components, consider these key decision factors:

- Material Certification: Confirm that your supplier provides verifiable certificates of analysis and compliance for Delrin grades, especially for regulated industries such as food processing or medical devices.

- Machining & Fabrication Capabilities: Evaluate whether the manufacturer offers CNC machining, injection molding, extrusion, and custom fabrication services to suit your project requirements.

- Experience & Industry Focus: Review the supplier’s track record in your specific sector, such as automotive, aerospace, electronics, or medical device manufacturing.

- Quality Assurance: Ensure robust quality control processes are in place, including dimensional inspection, surface finish verification, and compliance with ISO or industry-specific standards.

- Lead Time & Logistics: Assess the manufacturer’s ability to meet your timeline, provide just-in-time delivery, or manage inventory for ongoing projects.

- Technical Support: Look for suppliers who offer engineering guidance, material selection advice, and prototyping assistance to streamline your development process.

- Pricing & Value: While cost is a factor, balance pricing with quality, service, and technical expertise to maximize your return on investment.

Ready to compare Delrin suppliers? Use our Delrin manufacturer directory to find and evaluate at least four top-rated companies. Each business profile highlights core competencies, certifications, and capabilities, with direct contact forms for quote requests. Take advantage of our website previewer to quickly assess supplier strengths, then submit a single RFQ to multiple manufacturers for competitive pricing and service options.

Frequently Asked Questions About Delrin

- Is Delrin food safe? Certain grades of Delrin are FDA-compliant and suitable for food contact applications. Always verify certification from your supplier.

- Can Delrin be 3D printed? While Delrin can be processed in some industrial 3D printers, it is more commonly machined or injection molded due to its high melting point and specialized processing requirements.

- What is the temperature range for Delrin? Delrin typically performs between -40°C to 120°C, with short-term exposure up to 150°C. For continuous high-temperature exposure, consult the manufacturer for suitable grades or alternatives.

- How does Delrin compare to nylon? Delrin offers lower moisture absorption and greater dimensional stability than nylon, making it preferable for high-precision or wet environments. However, nylon may provide better impact resistance in some cases.

- Does Delrin resist UV light? Standard Delrin can degrade with prolonged UV exposure. UV-stabilized grades are available for outdoor applications.

Start Your Search: Find the Best Delrin Material for Your Project

Whether you’re an engineer seeking Delrin sheet, rod, or tube stock, a procurement professional comparing price quotes for machined Delrin components, or a product designer evaluating material options for your next innovation, understanding Delrin’s unique properties and applications is essential to making an informed choice. Ready to explore suppliers, request samples, or get a custom quote?

- Looking for Delrin stock in sheet, rod, or tube form? Browse Delrin stock suppliers and compare material grades.

- Need a custom Delrin part fabricated? Contact expert plastic fabricators for CNC machining, injection molding, or prototyping.

- Not sure which Delrin grade is right for your application?

- Ready to get a quote? Use our simple RFQ form to reach multiple Delrin manufacturers at once.

Empower your next project with the strength, precision, and reliability of Delrin—contact trusted Delrin suppliers today and experience the engineering advantages that make Delrin the top choice for high-performance plastic components worldwide.

Die Cutting

Die Cutting Foam Fabricating

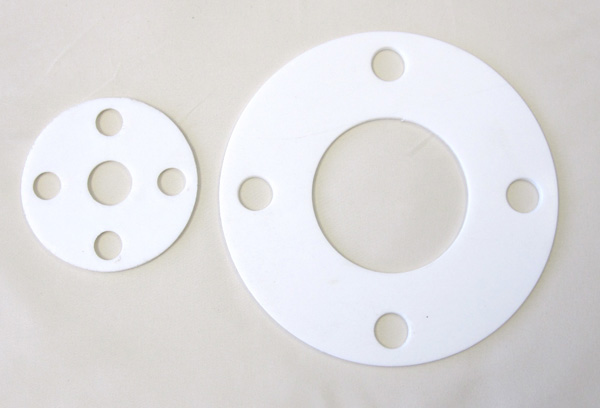

Foam Fabricating Gaskets

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

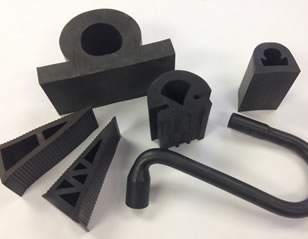

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services