United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

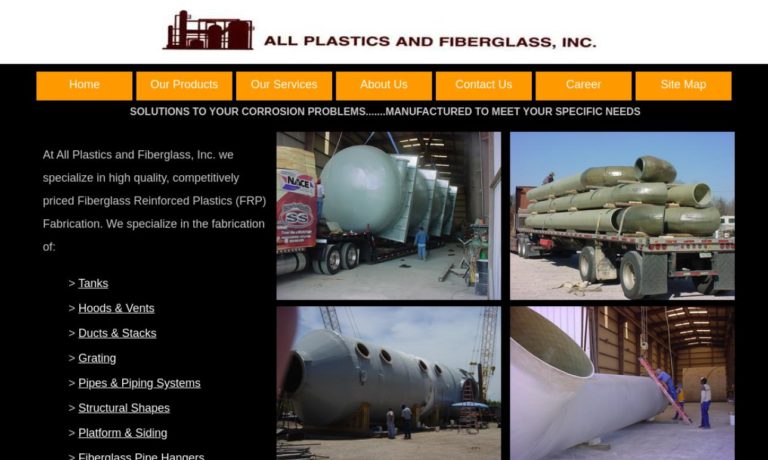

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

We are Boedeker Plastics, a leading supplier of high-performance plastics and composite materials. Our mission is to provide innovative solutions to our customers' most challenging material needs. With a focus on quality and customer satisfaction, we offer a comprehensive range of products and services to help our customers achieve their goals.

At ENSINGER Inc., we are dedicated to advancing the field of high-performance plastics by delivering materials that solve complex engineering challenges. We specialize in the development, production, and processing of thermoplastic materials that are engineered to perform in demanding applications across industries such as aerospace, automotive, medical, food processing, and industrial equipment.

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

More Acrylic Manufacturers

It is made of clear, thermoplastic resins that are found in acrylic acid and natural sources like petroleum. Like all thermoplastics, acrylic becomes pliable when heated and rigid when cooled.

Acrylic resembles glass aesthetically, but is half its weight as well as being resistant to sun and salt damage. Other positive characteristics that make acrylic a desirable thermoplastic that buyers want to purchase are its excellent insulation and transparent nature, which is actually clearer then glass.

Acrylic is able to be cut in thick chunks while still being fully transparent, while glass cutting may be a much more varied and expensive process. Glass also develops a greenish tint when cut thick. Acrylic manufacturers can fabricate products in a diverse range of shapes. Stock shapes, including sheet, rod, tube, film and plate forms, are most common.

However, acrylic manufacturers often accept special and custom orders to fit any need. Acrylic can also refer to paints used by artists that contain acrylic resin. Acrylic paints are desirable because they can take on a variety of looks when diluted but become water-resistant when dry. Artists have been using acrylic paint since the 1950s. Sometimes the artworks created with these paints are called acrylics as well.

Other uses for acrylic plastics are wide spread and varied. Because of its favorable qualities, including its ability to be flawlessly shaped, acrylics are utilized by many industries. The fact that there are two major types of acrylics also provides buyers with a variance in price. The extruded process creates a softer and cheaper product, but this kind of acrylic also scratches easily and contains impurities.

The cell cast process generates a more expensive but higher quality acrylic material. Acrylic manufacturers would most likely use the cell cast process for more rugged applications or applications where aesthetics are important. For example, aquariums would probably use the cell cast acrylic, since they can have them seamlessly shaped through chemical welding, and require a sturdy and scratch resistant material to give viewers the best aquatic experience safely.

Homes and offices often have acrylic windows and sliding doors, while shower doors and skylights are also often made from the thermoplastic. Since windows and doors are essential to most industries, such as hospitals, manufacturing plants, commercial buildings and so forth, acrylic is pretty popular. Also, because acrylic that is one inch thick or thicker is bullet-proof, prisons and security construction companies and automotive shops all use acrylic for specialized products where safety is a concern.

Die Cutting

Die Cutting Foam Fabricating

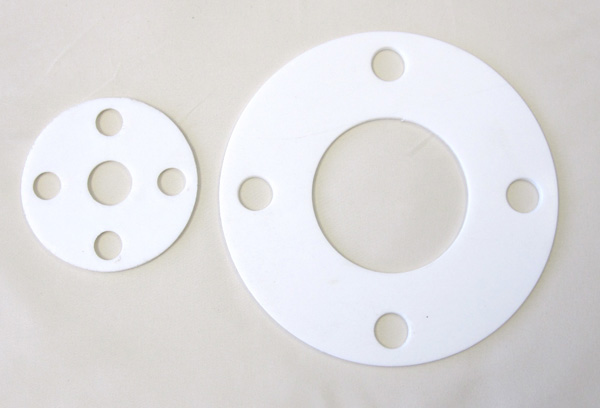

Foam Fabricating Gaskets

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

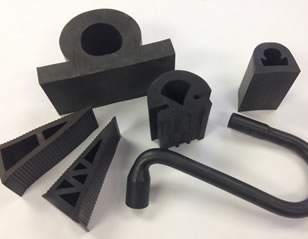

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

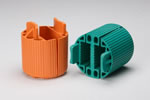

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services