Petro Extrusion Technologies, Inc.

Petro Extrusion Technologies, Inc.Request A Quote

Middlesex, NJ | 800-229-3338https://www.petroextrusion.com

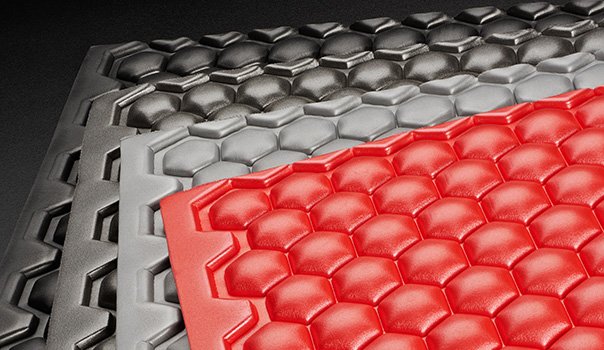

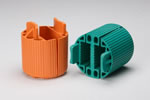

Petro Extrusion Technologies, Inc., located in Middlesex, New Jersey, is a renowned leader in the field of plastic extrusion. With over forty years of experience, Petro has consistently pushed the boundaries of innovation, making significant advancements in plastic extrusion technology. At Petro Extrusion Technologies, their expertise lies in plastic extrusion, a process that involves shaping and forming plastic materials into desired profiles. With their deep knowledge and experience, Petro has developed five stock plastic profile shape lines, including the highly acclaimed Nyla-Glide GR™, MDS-filled Nylon 6 channel line. This line offers a diverse range of over 15 stock C and U shape channels, specially designed for wear and edge trim applications. These channels provide exceptional performance and durability, meeting the demanding requirements of various industries. In addition to their stock product lines, Petro Extrusion Technologies offers a vast array of custom plastic extrusion capabilities. Their experienced team collaborates closely with clients to understand their specific requirements and develop customized solutions tailored to their needs. This flexibility allows Petro to cater to unique projects and deliver precise and high-quality plastic extrusions that meet the exact specifications of their customers. Petro Extrusion Technologies boasts an impressive selection of eight stock product lines, showcasing their commitment to offering a wide range of options to meet diverse application needs. Among these lines are three stock plastic extruded tubing lines, providing various sizes and materials to accommodate different industry requirements. Additionally, Petro offers five lines of stock plastic product shapes, expanding their offerings to include profiles beyond tubing. These product shapes are designed with precision and manufactured to meet rigorous quality standards. The dedication to quality and customer satisfaction is paramount at Petro Extrusion Technologies. They employ advanced manufacturing techniques and adhere to stringent quality control measures to ensure the production of top-notch plastic extrusions. Petro's commitment to excellence is evident throughout their processes, from material selection to extrusion, finishing, and packaging. Every step is carefully monitored and executed to guarantee the delivery of high-quality products to their valued customers. Petro Extrusion Technologies prides itself on being a trusted partner in the industry, with a commitment to innovation, precision, and customer-centricity. Their expertise, combined with their vast range of stock products and custom capabilities, positions them as a leading provider of plastic extrusion solutions. From wear and edge trim applications to tubing and various product shapes, Petro Extrusion Technologies has the expertise and resources to deliver the ideal plastic extrusion solutions for a wide range of industries and applications.

Die Cutting

Die Cutting Foam Fabricating

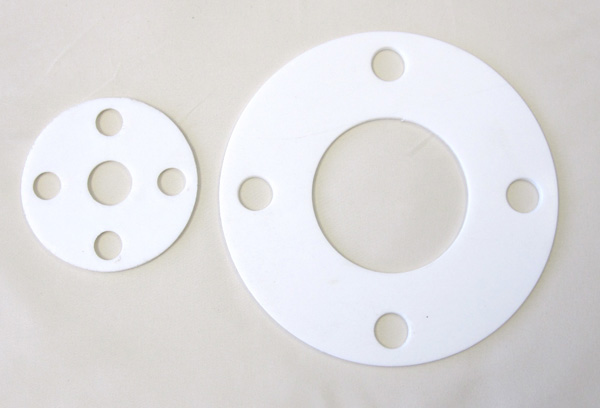

Foam Fabricating Gaskets

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

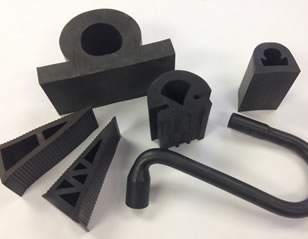

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services