More Plastic Materials Manufacturers

Plastics represent one of the most prevalent categories of synthetic materials worldwide, exhibiting properties similar to natural resins but offering dramatically increased versatility and performance. The term “plastic” is derived from Greek and Latin, highlighting its defining characteristic—the ability to be molded or shaped into countless forms. Valued for their adaptability, durability, and cost-effectiveness, plastics have become integral to nearly every commercial sector, transforming modern manufacturing, product design, and industrial processes around the globe.

What are Plastics?

At its core, plastic is a synthetic polymer designed to mimic the functional characteristics of natural resins. Resins are organic substances, typically secreted by plants as a protective mechanism, which are insoluble in water and possess a viscous consistency. They can range in color from clear to yellowish-brown and are flammable. Historically, resins gained economic importance due to their ability to harden and form strong polymer chains—traits that are mirrored in plastics but with far greater consistency and customization through chemistry.

While both plastics and natural resins share similar core behaviors—transitioning from a flexible or viscous state to a solid form—their chemical compositions diverge significantly. Plastics are engineered through the manipulation of monomers, allowing manufacturers to optimize for specific attributes such as strength, flexibility, impact resistance, or chemical stability. This synthetic approach unlocks an almost limitless array of applications for plastic materials, from everyday consumer goods to advanced industrial solutions.

Curious about how plastics compare to traditional materials?

History of Plastic Materials

The rise of plastic materials signifies a monumental economic and technological transformation. Over the last 150 years, plastics have steadily replaced traditional materials such as wood, glass, and metal, especially in the context of cost, performance, and mass manufacturing capabilities. The acceleration of plastic adoption has been particularly pronounced in the packaging, automotive, medical, and electronics industries, where plastic containers and components have become indispensable.

The journey of plastics began in 1862 when Alexander Parkes showcased “Parkesine”—an early form of plastic derived from cellulose—at the Great International Exhibition in London. Marketed as a cost-effective alternative to rubber, Parkesine (now known as celluloid) signaled the birth of an industry that would soon revolutionize material science.

The true dawn of the modern plastic era arrived in 1907, when Leo Baekeland invented Bakelite, the first fully synthetic plastic. This breakthrough coincided with global events such as World War I and II, which amplified the need for materials that were lightweight, durable, and easily mass-produced. The development of petroleum-based synthetic polymers during these periods led to the invention of iconic plastics such as polypropylene, PVC (polyvinyl chloride), polystyrene, and polyester. By the 1960s, plastics had become a defining symbol of convenience, modernity, and innovation in consumer and industrial products alike.

Want to discover how plastic manufacturing has evolved?

Types of Plastic Materials

Plastics can be broadly classified into two main categories: thermoplastics and thermosetting plastics (thermosets). This distinction is foundational to understanding their behavior, use cases, and suitability for different applications. Both types are synthesized from a variety of natural, organic, and synthetic monomers, allowing for precise control of properties such as flexibility, hardness, transparency, and resistance to heat or chemicals.

- Thermoplastics – These are plastics that become soft and pliable when heated, and can be reshaped or remolded multiple times without significant chemical change. This reversible process makes thermoplastics highly desirable for mass production and recycling. They are available as preformed shapes (sheets, rods, tubes) or as resins for molding processes. However, they may become brittle at low temperatures.

- Thermosetting plastics – Unlike thermoplastics, thermosets undergo an irreversible chemical change when heated and molded. Once cured, they form a rigid, cross-linked molecular structure that cannot be remelted or reshaped. This makes thermosets ideal for applications requiring structural integrity and heat resistance but limits their recyclability.

Each category encompasses a wide range of plastic polymers, each engineered for specific performance metrics.

Need help choosing the right type of plastic for your project?

Producing Plastic Products

The plastic manufacturing process begins with the production of plastic resins—the building blocks of all plastic products. This process, often called “cracking,” involves heating petrochemical feedstocks like crude oil or natural gas to break them into smaller hydrocarbon molecules such as ethylene and propylene. Depending on the desired end product, these hydrocarbons are then polymerized into long-chain molecules (polymers) with the aid of catalysts in a tightly controlled environment.

Once created, these polymers are processed into plastic resins. The properties of the final plastic material are determined by the choice of polymer and the addition of various additives. Manufacturers may blend resins with substances such as fillers (for strength or cost reduction), heat stabilizers (for thermal performance), lubricants (for processability), or plasticizers (for flexibility). Color can be introduced at this stage through pre-colored pellets or advanced masterbatching techniques, ensuring precise and consistent hues for branding, identification, or aesthetic requirements. Modern quality control systems—both visual and instrumental—ensure that products meet stringent industry standards.

Plastic resins can be processed into finished goods using a variety of manufacturing techniques, each optimized for specific product types and production volumes:

- Injection Molding – The most common plastic fabrication method, where molten resin is injected into a steel mold under high pressure to create complex, high-precision parts. Used for automotive components, consumer electronics, medical devices, and packaging.

- Blow Molding – Similar to injection molding but includes a step where compressed air inflates the heated resin into a hollow mold cavity, producing bottles, containers, and fuel tanks.

- Extrusion – Resin is melted and forced through a shaped die to produce continuous products such as pipes, tubes, window frames, and plastic films.

- Thermoforming & Vacuum Forming – A plastic sheet is heated until pliable, then shaped over a mold using vacuum pressure. Common for packaging, trays, and disposable cups.

- Compression Molding – Primarily used for thermosetting plastics: powdered resin is placed in a heated mold, where it melts, flows, and cures into its final form (found in electrical components, appliance housings, and automotive parts).

- Rotational Molding – A mold is filled with powdered plastic and rotated while being heated, creating large, hollow parts like tanks, playground equipment, and coolers.

Other specialized plastic fabrication methods include pultrusion (for reinforced profiles), foam extrusion (for insulation and packaging), precision machining (for custom parts), pressure forming, plastic welding, grinding, and casting. The choice of manufacturing process depends on the plastic resin used, part geometry, production volume, and performance requirements.

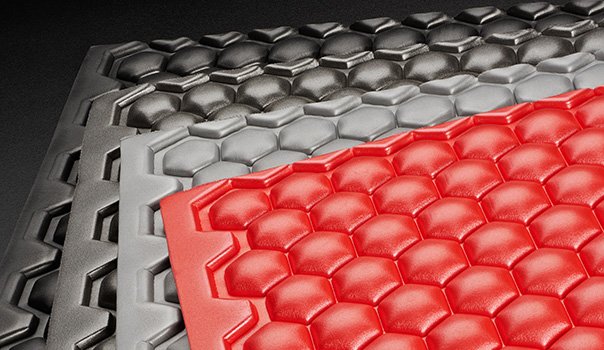

Plastic stock is available in a variety of forms, such as films, rods, sheets, pipes, and profiles. These can be used as finished products or further processed and machined for specialized applications.

Have specific manufacturing requirements? Explore our in-depth guides:

- Understanding Injection Molding for Plastic Parts

- Plastic Extrusion: Key Techniques and Applications

Thermoplastics: Types and Use Cases

Thermoplastics represent the most widely used class of plastic materials, prized for their ease of processing, recyclability, and broad spectrum of properties. Key thermoplastic materials include:

Polyethylene (PE) – The world’s most produced plastic, with global annual output exceeding 80 million tons. Polyethylene is primarily used in packaging applications—shampoo bottles, milk cartons, plastic bags, films, filters, and geomembranes. Its subtypes include:

- LDPE (Low-Density Polyethylene) – Flexible, used for grocery bags and squeeze bottles.

- HDPE (High-Density Polyethylene) – Rigid, strong, used in detergent bottles, toys, and piping.

- UHMW (Ultra-High Molecular Weight Polyethylene) – Extremely durable, used in medical implants and high-wear industrial parts.

Polyethylene Terephthalate (PET or PETE) – The most common plastic for beverage bottles, food containers, and synthetic fibers. PET is chosen for its clarity, toughness, and excellent moisture and chemical resistance, making it a staple in the food and beverage industry.

Polystyrene (PS) – Available as both rigid plastic and foam (Styrofoam), polystyrene is used in everything from disposable cutlery and CD cases to insulation, packaging, and craft materials. Extruded polystyrene foam provides outstanding thermal insulation for buildings and shipping containers.

Polypropylene (PP) – Recognized for its low friction, chemical resistance, and versatility, polypropylene is found in automotive components, textiles (such as diapers, thermal underwear), carpets, ropes, laboratory equipment, and food packaging. Its high melting point makes it ideal for dishwasher-safe containers and medical devices. Find polypropylene suppliers.

Delrin (Polyoxymethylene or Acetal) – This high-performance engineering thermoplastic is known for its strength, rigidity, and wear resistance, making it a popular metal replacement in precision gears, bearings, fasteners, and lock systems. Its low friction and dimensional stability are especially valued in automotive and industrial applications. Connect with Delrin manufacturers.

Polyvinyl Chloride (PVC) – One of the most versatile and widely used plastics, PVC is available in both rigid and flexible forms. Rigid PVC is used for pipes, window frames, and bottles, while flexible PVC (created with plasticizers) is found in electrical insulation, faux leather, flooring, and inflatable products. Its durability and resistance to chemicals and weathering make it ideal for construction, healthcare, and packaging. Research PVC suppliers and solutions.

Acrylic (PMMA, Plexiglass) – A clear, shatter-resistant thermoplastic often used as a glass substitute. Applications include skylights, signage, security barriers, aquariums, bathtubs, and automotive lighting. Acrylic combines optical clarity with good weather resistance, making it a favorite for displays and architectural features.

Polycarbonate (PC) – Known for impact resistance, optical clarity, and heat/flame resistance, polycarbonate is widely used in safety glasses, riot shields, electronic housings, automotive parts, and construction glazing. Its electrical insulating properties make it vital for electronic and telecommunications equipment.

Thermosets: Properties and Applications

Thermosetting plastics are distinguished by their rigid, cross-linked molecular structure, which forms during the curing process and cannot be reversed. Their unique properties make them essential for demanding industrial, automotive, and electrical applications where strength, heat resistance, and chemical stability are paramount. Key thermosetting plastics include:

- Epoxy Resins – Dominating the thermoset market, epoxies are valued for their exceptional adhesion, mechanical strength, and resistance to chemicals and moisture. Major use cases: adhesives, coatings, electrical encapsulation, composite materials (e.g., aerospace components, wind turbine blades), and floor coatings.

- Bakelite (Phenol Formaldehyde) – One of the earliest synthetic plastics, known for electrical insulation and heat resistance. Used in electrical switches, radio and telephone casings, and industrial machinery parts.

- Polyurethane (PU) – Highly adaptable, used in foams for furniture and bedding, insulation panels, automotive parts, adhesives, and coatings.

- Unsaturated Polyester Resins – Employed in fiberglass-reinforced plastics for boats, automotive parts, construction panels, and piping.

- Melamine Formaldehyde and Urea Formaldehyde – Used in laminates, kitchenware, and as adhesives in plywood and particleboard.

- Cyanate Esters and Other Advanced Thermosets – Used in aerospace, defense, and electronics due to their superior thermal and mechanical properties.

Thermosets are typically processed using compression molding, transfer molding, or casting, and are preferred when a combination of heat resistance and structural rigidity is essential.

Advantages of Plastic Materials

Plastic materials offer a wide range of advantages that explain their dominance in modern manufacturing and product design:

- Formability and Design Flexibility – Easily molded into complex shapes and intricate designs, plastics enable innovative product engineering across industries.

- Lightweight and High Strength-to-Weight Ratio – Plastics often outperform metals and glass in weight-sensitive applications, such as automotive, aerospace, and packaging.

- Cost-Effectiveness – Synthetic production processes and mass manufacturing yield significant cost savings over traditional materials.

- Durability and Chemical Resistance – Plastics resist corrosion, moisture, UV radiation, and a wide variety of chemicals, ensuring long service life in demanding environments.

- Thermal and Electrical Insulation – Many plastics provide excellent insulating properties, making them vital for electrical, electronic, and construction applications.

- Ease of Customization – Additives, fillers, and advanced processing techniques allow plastics to be tailored for specific properties, colors, and branding requirements.

- Recyclability – Many thermoplastics can be recycled and repurposed, supporting sustainability initiatives and circular economy models.

As a result, plastics have enabled cost reductions, enhanced safety, improved product performance, and expanded the scope of what’s possible in design and engineering.

Considering switching to plastic components?

Applications for Plastic Materials

Plastics have become essential material solutions across virtually every industry, thanks to their adaptability, durability, and performance. Common application areas include:

- Aerospace – Lightweight composites and structural plastics reduce aircraft weight, improve fuel efficiency, and resist harsh environments.

- Automotive – Plastics are used in body panels, interiors, engine components, lighting, dashboards, and fuel systems, supporting lighter vehicles and improved fuel economy.

- Medical Devices – Biocompatible plastics are critical for syringes, IV bags, implants, diagnostic equipment, and surgical tools, offering sterility and design flexibility.

- Packaging – PET, HDPE, and polystyrene dominate the packaging industry, enabling safe, lightweight, and cost-effective containers, films, and wraps.

- Construction – PVC pipes, insulation, window frames, and acrylic glazing offer durability, weather resistance, and energy efficiency for buildings and infrastructure.

- Electronics – Plastics provide electrical insulation, light-weighting, and flame resistance in housings, connectors, and circuit boards.

- Water Treatment – Corrosion-resistant plastics are used in piping, tanks, and filtration systems, ensuring safe water delivery and processing.

- Consumer Goods – From toys and kitchenware to sports equipment, furniture, and electronics, plastics offer performance, color variety, and functional design.

Every industry requires specific plastic materials to meet unique performance, safety, and regulatory requirements. For example, the food and beverage sector prioritizes plastics that are food-safe, heat-resistant, and chemical-resistant, while aerospace and automotive sectors demand lightweight, high-strength composites.

Searching for industry-specific plastic solutions? Explore:

- Medical-Grade Plastics: Properties and Applications

- Plastics in Automotive Manufacturing

- Innovations in Plastic Packaging

Considerations for Choosing a Plastic Supplier

With the vast range of plastic materials and specialized fabrication techniques available, selecting the right plastic manufacturer or supplier is crucial to achieving your technical, quality, and business objectives. Here are key factors to consider:

- Material Expertise – Does the supplier offer an extensive portfolio of plastic resins and blends suited to your application (e.g., engineering plastics, commodity plastics, specialty polymers)?

- Quality Assurance – Look for suppliers with robust quality control processes, raw material traceability, and industry certifications (such as ISO 9001, FDA compliance, or UL listing).

- Manufacturing Capabilities – Can the manufacturer provide the required processing methods (injection molding, extrusion, blow molding, machining, etc.) and handle your expected order volumes?

- Customization and Color Matching – Assess the supplier’s ability to match specific colors, produce custom blends, or provide proprietary formulations meeting tight tolerance or regulatory requirements.

- Customer Service and Responsiveness – Responsive support, technical assistance, and short lead times are critical, especially for prototyping, sampling, and urgent production needs.

- Logistics and Delivery – Evaluate their shipping capabilities, warehousing options, and ability to supply consistent volumes of resin or finished parts on time.

- Industry Reputation and Experience – Read customer reviews, check references, and consider their track record in your industry.

Partnering with a reliable, experienced plastic supplier can streamline your supply chain, improve product quality, and reduce long-term costs. Over time, consolidating your purchasing with a trusted supplier can also result in improved pricing, technical support, and strategic collaboration.

How do you choose the best plastic supplier for your needs?

Ready to request quotes or compare manufacturers? Start your search: Browse More Plastic Materials Manufacturers

Frequently Asked Questions About Plastic Materials

- What are the most common types of plastics and their uses?

Common plastics include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), polyethylene terephthalate (PET), and polycarbonate (PC). These are used for packaging, automotive parts, construction components, medical devices, and consumer products. - How do I select the right plastic material for my application?

Consider factors such as mechanical properties, chemical resistance, temperature tolerance, regulatory compliance, and cost. Working with an experienced supplier can help match the material to your specific requirements. - Are plastics recyclable and sustainable?

Many thermoplastics are recyclable, and advances in biodegradable and bio-based plastics are improving sustainability. However, recycling rates and environmental impact depend on local infrastructure and product design. - What are the latest innovations in plastic manufacturing?

Innovations include 3D printing with specialty polymers, bioplastics, nanocomposites, flame-retardant plastics, and smart materials with embedded sensors or antimicrobial properties. - How are plastics tested for quality and compliance?

Plastics undergo rigorous testing for tensile strength, impact resistance, thermal stability, chemical compatibility, and compliance with industry regulations (such as FDA, RoHS, REACH).

Summary: Why Plastics Matter in the Modern World

Plastics have emerged as one of the most transformative materials in industrial history. Their unique combination of versatility, efficiency, and adaptability drives advances in technology, medicine, transportation, architecture, and everyday life. As material science evolves, plastics continue to offer engineers, designers, and manufacturers an expanding toolbox of cost-effective and high-performance solutions. Whether you’re developing a new product, optimizing existing designs, or seeking sustainable alternatives, understanding plastic materials—and partnering with the right manufacturers—remains essential for success in today’s competitive marketplace.

Have more questions about plastic materials? Ask us directly.

Die Cutting

Die Cutting Foam Fabricating

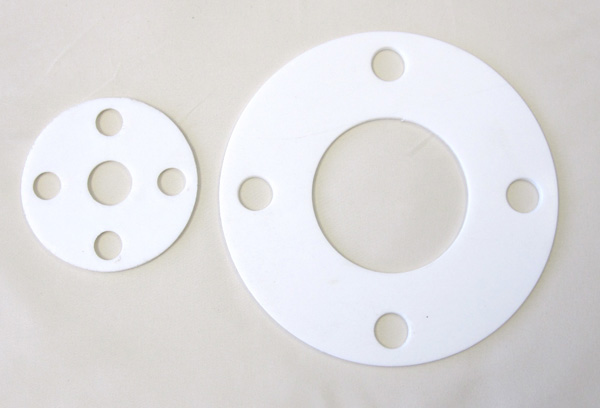

Foam Fabricating Gaskets

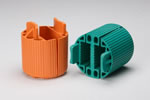

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

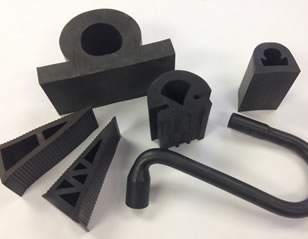

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services