United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

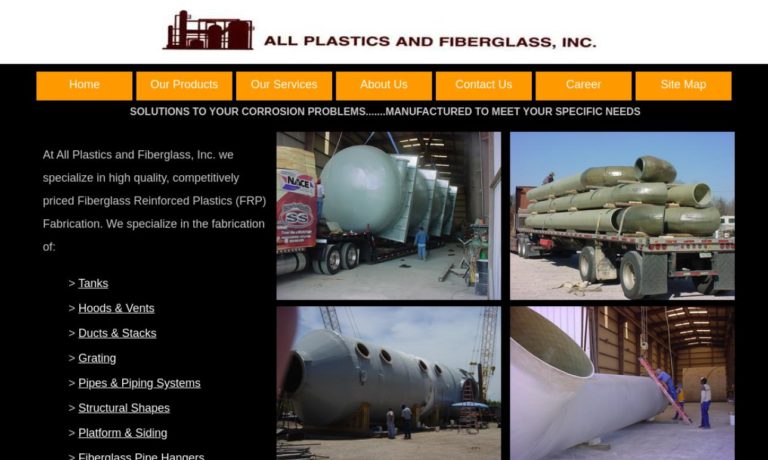

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

We are Boedeker Plastics, a leading supplier of high-performance plastics and composite materials. Our mission is to provide innovative solutions to our customers' most challenging material needs. With a focus on quality and customer satisfaction, we offer a comprehensive range of products and services to help our customers achieve their goals.

At ENSINGER Inc., we are dedicated to advancing the field of high-performance plastics by delivering materials that solve complex engineering challenges. We specialize in the development, production, and processing of thermoplastic materials that are engineered to perform in demanding applications across industries such as aerospace, automotive, medical, food processing, and industrial equipment.

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

More Plastic Sheet Manufacturers

Plastic Sheets: Applications, Manufacturing, and Industry Solutions

Plastic sheets are foundational materials in modern manufacturing, packaging, construction, and design. From lightweight and durable thermoforming plastic sheets to high-impact, chemically resistant panels, these versatile products serve vital roles across a spectrum of industries. Whether you’re seeking bulk plastic sheet suppliers for industrial applications or researching the right material for retail displays, understanding the properties, production processes, and use cases for plastic sheets is crucial for making informed purchasing decisions.

What Are Plastic Sheets?

Plastic sheets are flat, thin pieces of plastic material available in a range of thicknesses (gauges), sizes, colors, and surface finishes. These sheets are manufactured from various thermoplastic polymers—such as polycarbonate, acrylic, PVC (polyvinyl chloride), polyethylene (HDPE, LDPE), polypropylene, polystyrene, and PETG. Each type of plastic sheet has distinct characteristics that make it suitable for specific applications, including mechanical strength, impact resistance, optical clarity, chemical stability, and ease of fabrication.

Key Industries and Applications for Plastic Sheets

Plastic sheeting’s adaptability and performance make it essential in numerous sectors. Below are some of the most common industries and their applications for plastic sheets:

- Packaging: Thermoformed plastic packaging sheets are used for blister packs, clamshell packaging, trays, and food containers. Thin-gauge sheets are especially valued for their clarity, formability, and barrier properties.

- Automotive: Automotive manufacturers utilize thick-gauge plastic sheets and blocks for interior panels, dashboards, trim, protective barriers, and custom-machined parts. Lightweight plastics help reduce vehicle weight, improve fuel efficiency, and enhance design flexibility.

- Aerospace: High-performance plastics like polycarbonate and acrylic are used for aircraft windows, partitions, light covers, and interior panels due to their strength-to-weight ratios and resistance to impact and UV radiation.

- Construction and Architecture: Durable and weather-resistant plastic panels are used for skylights, glazing, greenhouse panels, wall cladding, and protective barriers. Acrylic sheet manufacturers supply materials frequently used as glass alternatives in windows and partitions.

- Signage and Displays: Clear acrylic, polycarbonate, and PVC foam boards are chosen for signs, lightboxes, display stands, and point-of-purchase (POP) displays due to their printability, formability, and aesthetic appeal.

- Food Processing: FDA-compliant plastic sheets like HDPE and polypropylene are used for cutting boards, conveyor components, and processing surfaces that require hygiene and chemical resistance.

- Marine and Outdoor: UV-stabilized plastic sheets are ideal for marine windshields, seating, instrument panels, and outdoor protective covers, offering excellent resistance to saltwater and weathering.

- Medical and Pharmaceutical: Medical-grade plastic films and sheets are employed in sterile packaging, instrument trays, and barrier applications where biocompatibility and cleanliness are required.

How Are Plastic Sheets Manufactured?

The plastic sheet manufacturing process involves several technologies, with extrusion being the most common. Here’s an overview of how plastic sheets are typically produced:

- Material Preparation: Plastic sheet manufacturers begin by selecting the appropriate polymer resin—these may include HDPE, LDPE, PETG, PVC, polypropylene, polystyrene, acrylic, or others—depending on the end-use requirements.

- Feeding and Melting: Plastic pellets or flakes are fed into a hopper, which conveys the raw material into a heated screw extruder. The screw mechanism shears and pushes the plastic forward, melting it through friction and heat into a uniform, molten state.

- Extrusion and Shaping: The molten plastic is pushed through a flat die, forming a continuous sheet. For certain applications, the die may be round or specialized to produce different sheet profiles. The sheet is pulled and stretched to the desired width and thickness by rollers and grips.

- Calendering and Cooling: The hot plastic sheet passes through a series of metal cooling rollers called calenders to achieve precise thickness and a smooth finish. The sheet is then cooled and either wound onto spools (for thin films) or cut and stacked flat (for thick-gauge sheets).

- Finishing: During or after calendering, additives such as UV stabilizers, anti-static agents, or surface coatings may be applied to enhance specific performance properties—such as weatherability, printability, or chemical resistance.

Plastic Sheet Types by Material

Choosing the right type of plastic sheet is essential for optimal performance. Here are the most common materials and their benefits:

- Polycarbonate Sheets: Known for high impact resistance, optical clarity, and temperature tolerance—ideal for safety glazing, machine guards, and skylights.

- Acrylic Sheets (Plexiglas): Offer excellent optical clarity, weather resistance, and ease of fabrication. Common in signage, windows, aquariums, and POP displays.

- PVC Sheets: Rigid and durable, PVC is used for wall cladding, signage, and chemical-resistant applications. Available in clear and colored variants.

- HDPE and LDPE Sheets: High-density and low-density polyethylene are tough, chemical-resistant, and FDA approved for food contact. Used in cutting boards, liners, and marine panels.

- Polypropylene Sheets: Lightweight, flexible, and resistant to fatigue and chemicals. Popular in packaging, corrosion-resistant tanks, and medical trays.

- PETG Sheets: Combines clarity, durability, and easy forming—ideal for protective barriers, packaging, and displays.

- Polystyrene Sheets: Economical and easy to print, polystyrene is common in disposable packaging, craft, and model making.

- Specialty Plastic Sheets: Fluoropolymer (PTFE, Teflon), ABS, and engineered plastics are used in demanding industrial and high-temperature applications.

Thermoforming Processes: Vacuum Forming and Pressure Forming

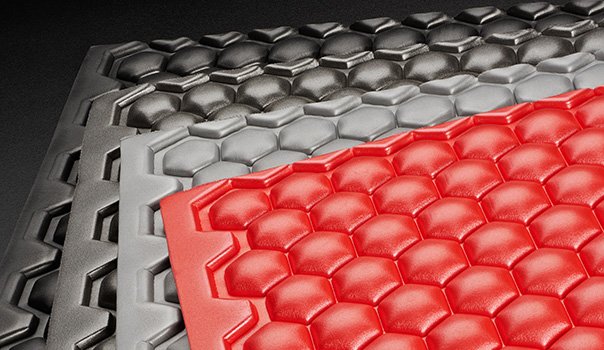

Thermoforming is a widely used method for converting plastic sheets into three-dimensional products. The most common processes are vacuum forming and pressure forming:

- Vacuum Forming: A plastic sheet is heated until pliable, draped over a male mold, and vacuum is applied to pull the sheet tightly against the mold, capturing its shape. This method is efficient for producing shallow, detailed parts such as packaging trays, inserts, and covers.

- Pressure Forming: Similar to vacuum forming, but uses a female mold and additional air pressure to force the heated plastic sheet into every detail of the mold. This is preferred for high-definition parts, medical device housings, and components requiring sharp detail and textured finishes.

Other thermoforming techniques include twin-sheet forming (for hollow, double-walled parts) and inline thermoforming (continuous, automated production for packaging and disposable products).

Buyer's Guide: Factors to Consider When Choosing Plastic Sheets

When sourcing plastic sheets for your project or business, comparing materials and suppliers is essential. Consider these key decision factors:

- Material Properties: Assess impact strength, chemical resistance, weatherability, optical clarity, and compliance with industry standards (such as FDA, UL, or ASTM).

- Thickness and Dimensions: Determine the right gauge and sheet size for your application. Standard plastic sheet thicknesses range from 0.010" (films) up to 4" or more (block plastics).

- Surface Finish and Color: Options include gloss, matte, anti-glare, textured, clear, translucent, or custom colors for branding and aesthetics.

- Formability and Machinability: Some plastics are easier to cut, drill, bend, or thermoform than others. Consult with your plastic sheet supplier for recommendations based on your fabrication needs.

- Cost and Availability: Pricing varies by material, thickness, and volume. Bulk orders and custom production may have longer lead times.

- Sustainability: Ask about recycled content, recyclability, and environmental certifications if eco-friendly plastic sheets are a priority.

Are you wondering how to choose the right plastic sheet for your application?

Common questions include:

- What is the best plastic sheet for outdoor use or UV exposure?

- Which plastic sheets are safe for food contact or medical applications?

- How do I compare acrylic vs. polycarbonate sheets for impact strength and clarity?

- Where can I find local or online plastic sheet suppliers with custom cutting services?

- What are the most cost-effective plastic materials for signage or packaging?

- Can I order plastic sheets pre-cut or with protective masking for fabrication?

For answers to these and more, contact a plastic materials expert or explore our guides on plastic sheet selection, comparison, and sourcing.

Benefits of Using Plastic Sheets

Plastic sheets offer numerous advantages over glass, metal, or wood in many applications. Benefits include:

- Lightweight: Easier to transport, handle, and install compared to glass or metal panels.

- Impact Resistance: Many plastics (such as polycarbonate) are virtually unbreakable, making them ideal for safety glazing and protective barriers.

- Weatherability: UV-stabilized plastics resist yellowing, cracking, and degradation in outdoor environments.

- Chemical Resistance: Suitable for harsh environments, laboratories, and chemical processing.

- Design Flexibility: Available in a vast array of colors, finishes, and thicknesses. Easily fabricated, printed, or thermoformed into complex shapes.

- Cost-Effectiveness: Lower material and installation costs, especially for large-scale projects or disposable products.

- Hygiene: Non-porous and easy to clean, ideal for food processing, medical, and cleanroom environments.

Real-World Use Cases: How Plastic Sheets Solve Industry Challenges

Wondering how plastic sheets are used to address specific business needs or technical challenges? Explore some practical examples below:

- Retail Displays: Acrylic and polycarbonate sheets are fabricated into custom display stands, shelving, sign holders, and sneeze guards for retail environments. Their clarity and durability enhance product visibility while protecting merchandise and staff.

- Architectural Glazing: Lightweight, shatter-resistant plastic sheets replace traditional glass in skylights, balcony barriers, partition walls, and greenhouses, improving safety and reducing installation costs.

- Machined Parts: Thick-gauge plastic stock is CNC machined into gears, wear strips, bushings, and custom components for industries such as petrochemical, food processing, and transportation.

- Protective Barriers: During the COVID-19 pandemic, clear plastic sheets were widely adopted for social distancing barriers in offices, restaurants, and public spaces due to their transparency and ease of cleaning.

- Marine Applications: UV-resistant marine plastic sheets are used for boat windshields, instrument panels, and seating—offering long-term durability in harsh, saltwater environments.

- Food Industry: FDA-compliant HDPE and polypropylene sheets are converted into cutting boards, food prep surfaces, and packaging trays to maintain hygiene and product safety.

Frequently Asked Questions About Plastic Sheets

Looking to narrow down your search for the ideal plastic sheet product or supplier? Here are answers to common queries:

- What is the difference between acrylic and polycarbonate sheets?

Acrylic (Plexiglas) is known for its optical clarity and weather resistance, while polycarbonate offers greater impact strength and heat resistance. Polycarbonate is often chosen for safety glazing, machine guards, and security applications, while acrylic is preferred for displays, aquariums, and windows. - Are plastic sheets recyclable?

Many plastic sheets—especially those made of PETG, polycarbonate, and acrylic—are recyclable. Check with your supplier for recycling programs or local facilities that accept post-industrial or post-consumer plastic scrap. - Can I order custom-cut plastic sheets?

Yes, most reputable suppliers offer custom cutting, drilling, and fabrication services to meet your specific size and shape requirements. This reduces waste and improves installation efficiency. - How do I clean and maintain plastic sheets?

Use mild soap and water with a soft, non-abrasive cloth. Avoid harsh chemicals or solvents that may damage the surface. Some plastics are available with anti-scratch or anti-static coatings for enhanced durability. - What are the lead times for bulk plastic sheet orders?

Lead times vary based on material, thickness, color, and order volume. Standard items may ship in a few days, while custom or specialty orders can take several weeks. Confirm with your supplier when placing large or custom orders.

How to Source Plastic Sheets: Finding Trusted Suppliers

Ready to purchase plastic sheets for your next project? Follow these steps to ensure you receive the best quality and value:

- Define Your Requirements: Identify the material, thickness, size, color, and any special properties (UV resistance, food-safe, etc.) needed for your application.

- Research Suppliers: Look for established plastic sheet distributors, manufacturers, and online retailers with strong reputations, wide material selection, and custom fabrication capabilities.

- Request Quotes: Compare pricing, lead times, and minimum order quantities. Don’t forget to inquire about shipping costs and packaging options, especially for large or fragile sheets.

- Check Certifications: Ensure the products meet relevant industry standards and certifications for safety, performance, and sustainability.

- Ask About Value-Added Services: Many suppliers offer CNC machining, laser cutting, bending, and finishing for turnkey solutions.

- Read Reviews and Case Studies: Customer feedback and project success stories can help you evaluate supplier reliability, product quality, and service.

Need help selecting the right plastic sheet material or supplier? Contact our team of plastics experts or browse our plastic sheets product catalog for detailed specifications, comparison guides, and application insights.

Conclusion: Maximizing Value with the Right Plastic Sheet Solution

Plastic sheets remain indispensable in modern industry, design, and manufacturing. Their versatility, strength, and customizability make them the material of choice for applications ranging from packaging, displays, and glazing to machine parts and marine components. By understanding the unique benefits of each plastic type, the manufacturing processes, and the factors that impact performance and cost, you can make informed decisions that maximize quality, efficiency, and value.

Ready to get started? Connect with a plastic sheet specialist for personalized recommendations, or explore our full range of plastic sheet products to find the perfect match for your application.

Die Cutting

Die Cutting Foam Fabricating

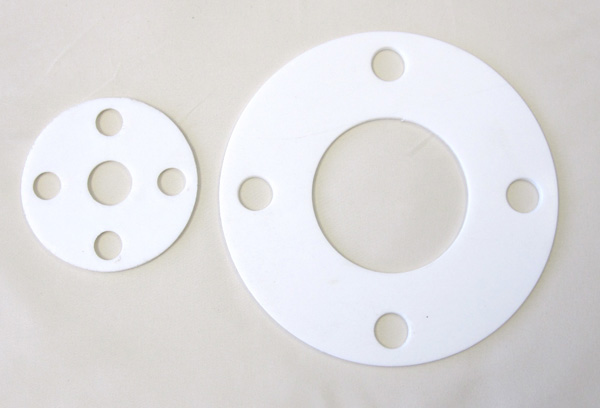

Foam Fabricating Gaskets

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

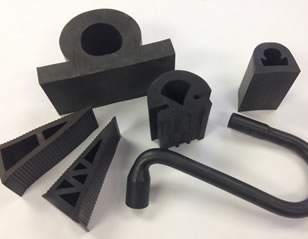

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services